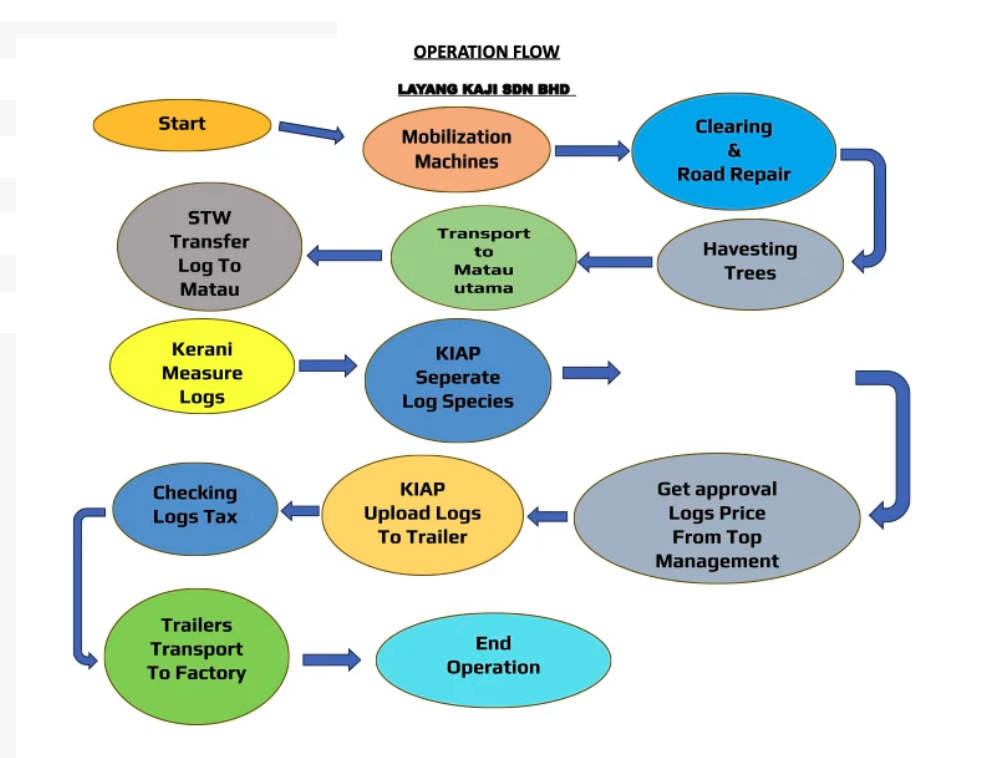

Complete Forest Management Workflow

Step-by-Step Operation Flow

Start

Initiation of forest management operations. This marks the beginning of the comprehensive workflow that ensures systematic and compliant forest operations from start to finish.

Mobilization Machines

Deployment and positioning of heavy machinery and equipment to the designated forest operation site. This includes bulldozers, excavators, chainsaws, and other essential equipment required for the operation.

Clearing & Road Repair

Site preparation including clearing of undergrowth, repair and construction of access roads, and establishment of safe working areas. This ensures proper access for machinery and personnel while minimizing environmental impact.

Harvesting Trees

Selective felling of approved trees according to the forest management plan. This process follows strict guidelines to ensure sustainable harvesting while preserving the forest ecosystem and biodiversity.

Transport to Matau Utama

Transportation of harvested logs from the felling site to the main landing area (Matau Utama). This central collection point serves as the hub for further processing and sorting operations.

STW Transfer Log To Matau

Systematic transfer and organization of logs at the landing area using specialized equipment. STW (San Ta Wong) operations ensure efficient handling and positioning of logs for subsequent processing steps.

Kerani Measure Logs

Precise measurement and documentation of log dimensions by trained clerks. This includes recording length, diameter, and volume calculations to determine the total tonnage (TAN) for inventory and pricing purposes.

KIAP Separate Log Species

Sorting and categorization of logs by species type using KIAP (specialized sorting equipment). This ensures proper classification for different market demands and maintains quality standards for various timber grades.

Get Approval Logs Price From Top Management

Obtaining pricing approval from senior management based on current market conditions, log quality, and species type. This ensures competitive pricing while maintaining profitability and market standards.

KIAP Upload Logs To Trailer

Loading of sorted and approved logs onto transport trailers using KIAP equipment. This process ensures safe and efficient loading while maintaining log quality and maximizing trailer capacity.

Checking Logs Tax

Verification and calculation of applicable taxes and duties on the timber shipment. This includes compliance with local and federal tax regulations, ensuring all legal requirements are met before transport.

Trailers Transport To Factory

Final transportation of processed logs to manufacturing facilities or mills. This step completes the forest-to-factory supply chain, ensuring timely delivery while maintaining log quality and documentation.

End Operation

Completion of the forest management operation cycle. This includes final documentation, site cleanup, equipment demobilization, and preparation for the next operational phase or site restoration activities.

Comprehensive Forest Management Workflow

Our standardized operating procedures ensure efficient, sustainable, and compliant forest operations from initial site preparation to final timber delivery. Each step is carefully monitored and executed by trained professionals to maintain the highest standards of environmental stewardship, safety, and operational excellence.

Partner with Malaysia'sForest Management Leader

Join us in creating sustainable forest solutions that benefit communities, preserve biodiversity, and drive economic growth.